The global metal manufacturing landscape is increasingly driven by precision and efficiency, and nowhere is this more evident than in metal fabrication. Laser tube cutting has totally changed how industries like automotive, aerospace, construction and furniture cut complex metal tubes and profiles. China, as the world’s manufacturing hub, is home to the most innovative and competitive tube laser cutting machine manufacturers. The reason is that their machines can offer non-negligible combination of tube cutting speed, precision and operational safety.

I. Ranking List of Chinese Laser Tube Cutting Machine Manufacturers

In 2025 and beyond, the global customers’ focus is and will be put on the smarter, more integrated, and highly automated manufacturing solutions.

1. Han’s Laser

○ Key Advantages: As one of China’s largest laser corporations, Han’s Laser boasts massive R&D resources and a complete product ecosystem. Their strength lies in their ability to provide integrated automation solutions and their brand reputation for innovation.

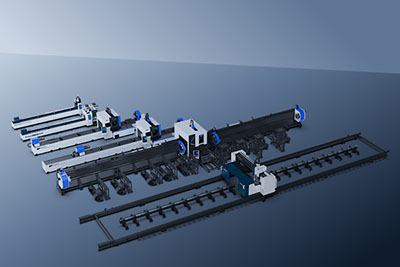

○ Product Categories: A comprehensive suite of laser tube cutting machines, incl. economical models, high-end, fully automated lines, standard & specialized machines and automation options to provides various automated material handling solutions.

○ After-Sales Service & Support: Cover the Asia, Europe and Americas, such as China, Japan, South Korea, India, Thailand, Vietnam, Philippines, Malaysia, Germany, USA, Canada.

○ Ideal For: A wide range of users, from large corporations needing custom-made automated production lines to smaller shops relying on a trusted brand name.

2. SENFENG

○ Key Advantages: SENFENG has built a formidable reputation across the globe by offering exceptional value for money. They focus on high performance, cost effectiveness, and a incredibly variety of product portfolio to fit for various budgets and tube cutting needs.

○ Product Categories: After years of development, they can offer one of the widest ranges of tube laser cutting machines, including affordable models, low to high-power precision tube cutters (such as, one-chuck, two-chuck, three-chuck and four-chuck machines, special models for cutting profile steels and 3D cutting) and the combo of plate and tube cutting.

○ After-Sales Service & Support: SENFENG has a widespread service network across China and many international markets, with global coverage in over 100 countries and regions, with local subsidiaries and service centers in US (LA, Chicago, Houston), Germany, UAE, Pakistan, Jordan, India, Japan, Vietnam, just for localized installation, repair, maintenance and technical supports.

○ Ideal For: Large-sized businesses that desire high cutting precision, small and medium-sized enterprises (SMEs), workshops, and value-conscious buyers entering the laser cutting market or expanding their capacity.

3. HSG Laser

○ Key Advantages: HSG is a major player known for robust machine construction and a strong focus on the Chinese market. They offer reliable machines with user-friendly Chinese-language software and have a relatively large market share.

○ Product Categories: Offer a large range of tube laser cutting machines, from basic 3-axis models to advanced 6-axis machines for complex processing. They also provide combo machines that can cut both tube and flat sheet on a single platform.

○ After-Sales Service & Support: Maintain a strong and extensive service network across China and other foreign countries like Germany and USA, ensuring responsive technical supports, readily available spare parts, and online/offline operator training programs.

○ Ideal For: A broad customer base, from small-to-medium-sized job shops to large manufacturers in industries like metal furniture, fitness equipment, automotive parts and general fabrication.

4. HGLASER

○ Key Advantages: Backed by the prestigious Huazhong University of Science and Technology, HG Laser has strong roots in R&D and technical innovation. They are known for self-developing core laser technologies and offering stable, high-performance tube laser cutting machines.

○ Product Categories: They provide high-precision tube cutting systems, often working with smart factory software, as well as laser processing solutions for various industries.

○ After-Sales Service & Support: They can offer timely technical supports and have a reliable service team solving complex challenges.

○;þIdeal For: Technologically-focused companies and industries that require tailored, high-precision solutions and pay more attention to technical supports.

5. Hymson Laser

○ Key Advantages: Hymson Laser has carved a niche in providing turnkey production solutions. Their expertise is to integrate laser tube cutting with robotics and material handling to create high-throughput production lines.

○ Product Categories: Fiber laser tube cutting machines and turnkey automated production lines including tube cutting, bending, cleaning, and assembly for mass production (e.g., for battery trays, car frames).

○ After-Sales Service & Support: Hymson is committed to becoming a global leader in laser and automation technology innovation, and it has established 12 global subsidiaries in US, Germany, Hungary, Switzerland, Canada, Spain, Italy, South Korea, Singapore and so on.

○ Ideal For: Users in high-volume sectors like new energy (EV), white goods, and furniture who desire to automate their entire tube cutting workflow.

6. Longxin Laser

○ Key Advantages: Longxin Laser primarily specializes in tube laser cutting solutions. Their key advantage lies in deep expertise and the focused product line special for cutting pipes and profiles. They are famous for offering practical, cost-effective and well-targeted machines for tube-specific applications.

○ Product Categories: Their portfolio is focused exclusively on tube cutting machines. They can offer a variety of models at different laser power levels and tube handling capacities (e.g., round tube diameter, pipe length), incl. options with automatic loading/unloading systems.

○ After-Sales Service & Support: Provide reassuring after-sales service with focus on specific demands for tube cutting users and give timely supports includes new installation, maintenance, and application assistance to optimize tube cutting process.

○ Ideal For: Companies whose core business revolves around cutting metal tubes and profiles, such as manufacturers of furniture, shower rails, bicycle frames, store displays and HVAC ductwork.

7. Penta Laser

○ Key Advantages: Penta Laser is recognized for its fast tube laser cutting machines. They specialize in high-power applications (often 20kW and above), delivering superior cutting speed and capability while cutting thick-walled tubes in large

○ Product Categories: High-power fiber laser cutting systems for both tubes and plates, with a focus on heavy-duty industrial applications. Standard and automated models offering both manual load and automated cell configurations.

○ After-Sales Service & Support: Its machines have been exported to US, England, Germany, France, Australia, Japan, South Korea and other advanced countries and regions due to the local technical supports.

- þIdeal For: Heavy industrial manufacturers, construction equipment producers, and shipyards that need to process thick metals quickly.

8. ACME Laser

○ Key Advantages: ACME often regards itself as a technology-driven provider of precision laser machines. They emphasize cutting accuracy, stability and often incorporate features that raise ease of use and automation readiness during high-mix production.

○ Product Categories: Offer a range of precision tube laser cutters, incl. models capable of cutting small to medium-sized tubes at fast speed. Their machines also feature automatic focusing and support for cutting complex shapes at high precision.

○ After-Sales Service & Support: Offer a considerate service package that includes consultation, installation and training. They are trying to ensure high machine utilization and provide technical support to solve real-world challenges.

○ Ideal For: Engineering workshops, electronics companies and manufacturers producing high-value parts where precision and cutting quality are critical, such as in medical device, precision components and hi-end architectural elements.

9. Lingchuang Laser

○ Key Advantages: Known for developing the heavy-duty, industrial-grade laser cutting systems designed for high stability and continuous operation in high-demanding workplaces.

○ Product Categories: Produce large-format tube cutting machines that can handle long and heavy profiles, often with custom-made cutting solutions for specific users and industries.

○ After-Sales Service & Support: Offer a full life-cycle service model, from project planning to after-sales maintenance, so as to ensure high machine utilization rate.

Ideal For: Heavy industries, mining equipment manufacturers, and structural steel fabricators.

10. Share-win Laser

○ Key Advantages: It focuses on providing both cost-effective and practical tube cutting solutions. They have gained traction by offering reliable machines at competitive price, often featuring user-friendly operations.

○ Product Categories: Primarily focused on fiber laser tube and pipe cutting machines, catering to the standard profiling market.

○ After-Sales Service & Support: Their service is growing and is generally considered adequate for the needs of their target market, with good parts availability.

○ Ideal For: Start-ups, small job shops, and value-driven buyers making their first investment in laser tube cutting technology.

II. How to Choose the Right Manufacturer for Your Needs

Selecting the best partner goes beyond just the ranking. Also remember factors below:

○ Your Application: Define your type of tubes (material, thickness, shapes) needing to cut.

○ Automation: Do you require manual loading or a fully-automatic production cell?

○ Software & Support: Assess the user-friendliness of CNC system and the availability of local technical support and technical training.

○ Budget: Balance your upfront investment against long-term operational costs, maintenance, and potential ROI.

III. Making the Right Choice for 2025

The Chinese laser tube cutting market is vibrant and fiercely competitive, driving rapid innovation. For 2025, manufacturers like TRUMPF (China) and SENFENG are leading the charge by developing laser tube cutting technologies that were once only available from Western brands at a fraction of the cost. Whether you prioritize the absolute peak of precision from Bystronic, the exceptional value and performance from SENFENG, or individual solutions from others on this list, China still remains the premier destination for purchasing top-class laser tube cutting machines at low expenses. Thorough market survey and direct talks with these manufacturers is key to finding out the perfect tube laser cutting machine for your actual needs.