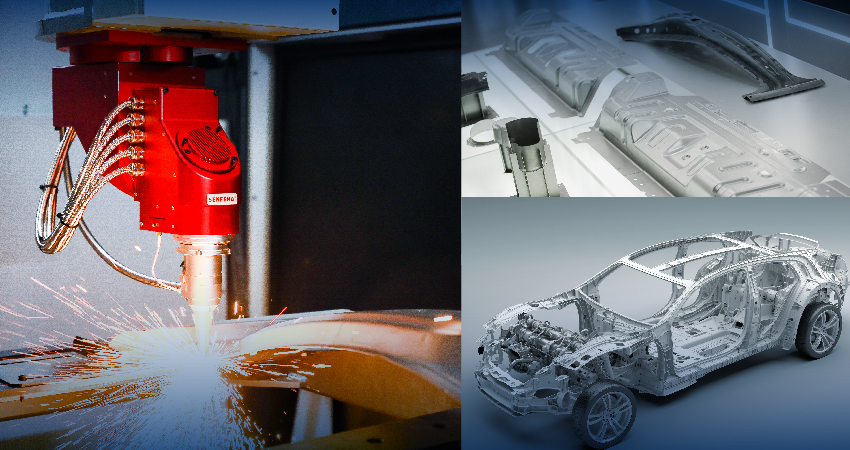

SENFENG has established R&D centers in both China and Paderborn, Germany to successfully develop laser generators, laser processing heads (cutting, welding and cladding), operating systems, machine tools and accessories.

– Over 100 R&D employees

– 700+ technical patents at home and abroad